Categories

Stainless steel Male straight stainless steel push in fittings Code

Tube Dia(mm) - Thread Size (R)/(G) | |

DSPC4-01(G) | DSPC12-01(G) |

DSPC4-02(G) | DSPC12-02(G) |

DSPC4-03(G) | DSPC12-03(G) |

DSPC6-01(G) | DSPC12-04(G) |

DSPC6-02(G) | DSPC14-02(G) |

DSPC6-03(G) | DSPC14-03(G) |

DSPC6-04(G) | DSPC14-04(G) |

DSPC8-01(G) | DSPC16-02(G) |

DSPC8-02(G) | DSPC16-03(G) |

DSPC8-03(G) | DSPC16-04(G) |

DSPC8-04(G) | |

DSPC10-01(G) | |

DSPC10-02(G) | |

DSPC10-03(G) | |

DSPC10-04(G) | |

Stainless steel Male straight Features

The materials ensure Anti-Corrasion highly, all of them are made from SUS316L/SUS304L except the seal ring.

FKM is used as the seal ring, which can ensure Anti-Corrosion and acid resistant, also can be used in high temperature.

The accessories are oil-free and reach the Food Hygiene Law of People's Republic of China. Which are applied widenly in the range of industry such as food service industry, chemical industry and medical industry.

Stainless steel Male straight stainless steel push in fittings Specifications

Fluid | Air & water&steam |

Operating Pressure | 0-1.5Mpa(150Psi) |

Max Pressure | 1.8Mpa |

Operating Temperature | .-20-220C |

Applicable tube | PU or Nylon |

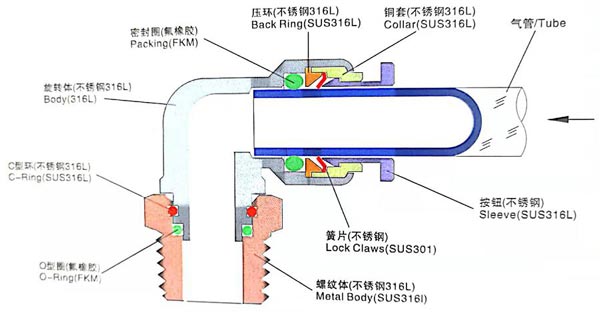

Structure Chart

What are the main types of stainless steel push-in fittings?

There are several types of stainless steel push-in fittings, including internal and external threading. Internal threading fittings are used for tubing connections, while external threading fittings are used for manifold connections.

How can I ensure the safety of stainless steel push-in fittings?

To ensure the safety of stainless steel push-in fittings, it is important to follow several best practices. First, ensure that the fittings are properly installed and tightened to the recommended torque. Second, avoid over-tightening, as this can damage the fitting. Third, clean the fitting before and after each use to prevent debris from entering the fitting. Finally, if you experience any leaks or failures, immediately replace the fitting.

What are the advantages and disadvantages of stainless steel push-in fittings compared to other materials?

Compared to other materials, stainless steel push-in fittings have several advantages. They are durable, resistant to corrosion, and easy to clean. However, they may be more expensive than other materials, and they may not be as strong as metal fittings.

How can I clean stainless steel push-in fittings?

To clean stainless steel push-in fittings, you can use a solvent or cleaning solution. Avoid using soap or detergent, as these can damage the fitting's surface. Simply immerse the fitting in the solution for a few minutes, then rinse with clean water.

What are the best practices for storing and transporting stainless steel push-in fittings?

To store and transport stainless steel push-in fittings, you should follow several best practices. First, store the fittings in a cool, dry place, away from sunlight. Second, avoid shipping with excessive force or vibration, as this can damage the fitting. Finally, label the fittings with their name, model number, and any important information.

Ningbo Define International Trading Co., Ltd. is an export-oriented enterprise specializing in joints, stainless steel pipe fittings, pneumatic and hydraulic components, electronic components, auto parts and plastic products, which are used in industrial automation, food, textile, chemical, automotive and other fields.

E-mail: jetding@pneufit.com

Mobile: 0086-15314521608

Tel: 0086-574-88936095

Fax: 0086-574-88936095

WhatsApp: +86-15314521608

Add: No 505, 30 building, Nanxi Homeland, Jinping Street Fenghua City, Ningbo, China